The Importance of Jar Testing in Water and Wastewater Analysis

A jar test is a pilot-scale laboratory test that simulates coagulation or flocculation with different chemical doses. The purpose of this test is to estimate the minimum coagulant dose required to achieve certain water quality goals. The jar test helps determine the right amount of treatment chemicals, or the lowest dose of chemicals needed to provide satisfactory settling.

Jar Testing and Flocculation

Jar testing helps you choose the correct chemical coagulants and dosage to remove suspended matter and pollutants from water treated in wastewater treatment plants.

The choice and dosage of chemical coagulants comes from the laboratory jar test results, which mimic the full-scale operation of a water treatment plant.

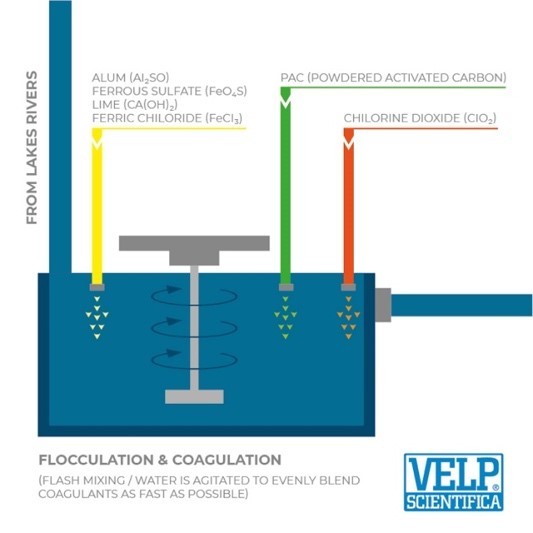

The most used coagulants are lime (calcium hydroxide), alum (aluminum sulphate), and iron salts (ferric or ferrous).

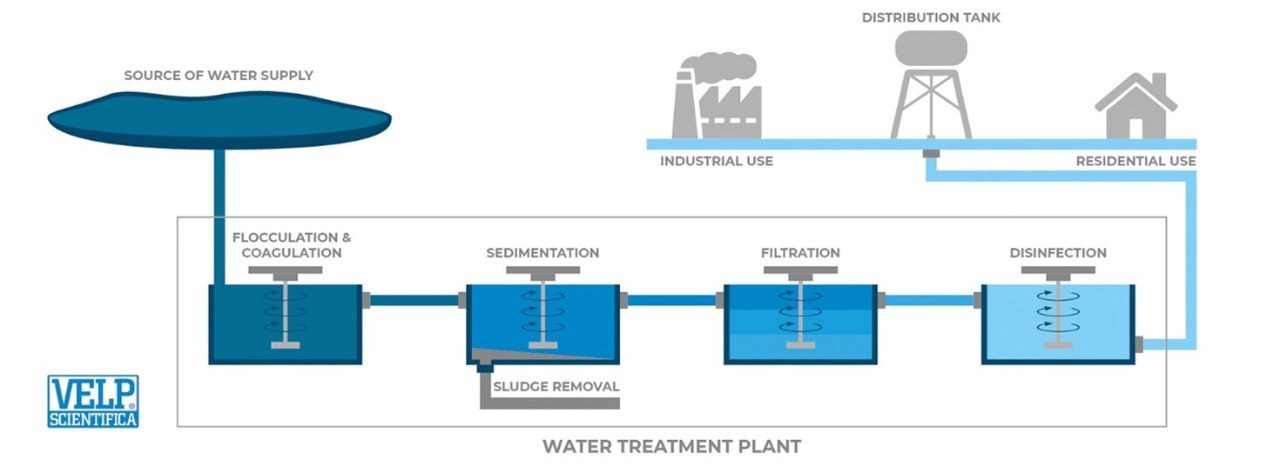

Flocculation or coagulation is fundamental in every water treatment process and it is a propaedeutic step for sedimentation, filtration, and disinfection before distributing water for residential and industrial use.

How It Works

Using a flocculator, the coagulant substance is added to the water sample beakers. The chemical coagulant starts to precipitate, trapping all the impurities and forming flocs that will deposit on the bottom of the beaker.

The sample is continuously stirred so the formation, development, and settlement of floc occurs like it would at a full-scale plant and can be observed.

The operator then performs a series of tests to compare the effects of different amounts of flocculation agents at different pH values to determine the right size floc.

The most common analytical conditions using a flocculator are:

- 1,000 mL glass beakers (jars), tall form, Ø 105 mm

- 600 mL wastewater samples and coagulants

- Paddles at the middle height of the sample

- Turbulent stirring at 120 rpm for 120 seconds

- Slow speed flocculation at 30 rpm for 25 minutes

- First evaluation of results after 5 minutes of sedimentation

Results Evaluation for Optimizing Performance

The results of a jar test can be evaluated based on different criteria:

- Floc dimension evaluation with a numerical degree

- Time from the addition of chemicals to the first appearance of flocs

- Evaluation of residual turbidity of the supernatant after a determined sedimentation time by turbidimeter

- Measurement of the electro-kinetic potential of suspended particles on a sample taken immediately after the addition and mixing of chemicals

- Determination of filterability of clarified water by standardized membrane filters under pressure (the reduction of water flow is related to clogged filters and residual, unsettled suspended matters)

VELP-Dedicated Solutions for Flocculation

The jar test helps water treatment plant operators avoid overfeeding or overdosing, especially with coagulants, saving resources and optimizing processes. VELP offers robust solutions for jar tests with strong resistance to chemical and mechanical corrosion. For example, VELP JLT and FCS Series Flocculators feature multiple stirrers and consistent speeds, a basic requirement for reliable results. An illuminated back panel enables simple and clear floc observation and evaluation for maximum reproducibility. These products also offer a digital display and timer, helping to meet the requirements of every lab.